TEHHIM MANUFAKTURA, LLC

Equipment for Foam Fire Suppression Systems

Operating principle of the bladder tank: When water is supplied into the tank containing a flexible bladder with foaming agent concentrate, the water affects on the bladder, compressing it and forcing the foam concentrate into the proportioning device (dispenser). Next, the foaming agent is fed through a dispenser into the water flow in the required proportion to ensure its desired concentration in the aqueous solution.

The capacity of the bladder tanks varies from 200 litres to 23,000 litres. Maximum operating pressure is 1.6 MPa, service life is 10 to 30 years. Range of operating temperatures is from +5 to +50°C. The standard material for manufacturing the tank and piping is steel 09Г2С grade. If necessary, the piping can be manufactured from 12X18H10T stainless steel. It is also possible to manufacture a bladder tank according to the customer's individual specifications.

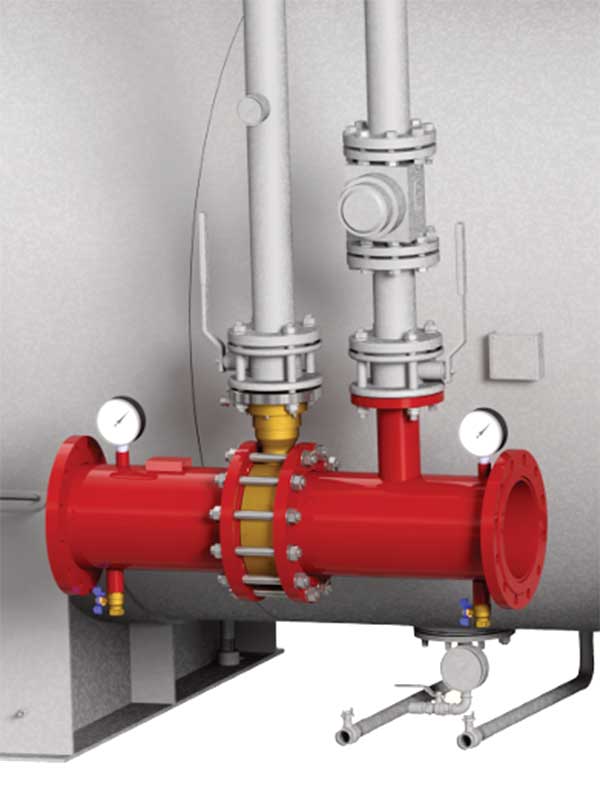

Depending on the project, one or more dispensers may be installed on the tank(s). The dispenser is installed directly on the tank (standard version) or remotely from it. The distance for the remote dispenser location should not exceed 10 metres.

The capacity of the bladder tanks varies from 200 litres to 23,000 litres. Maximum operating pressure is 1.6 MPa, service life is 10 to 30 years. Range of operating temperatures is from +5 to +50°C. The standard material for manufacturing the tank and piping is steel 09Г2С grade. If necessary, the piping can be manufactured from 12X18H10T stainless steel. It is also possible to manufacture a bladder tank according to the customer's individual specifications.

Depending on the project, one or more dispensers may be installed on the tank(s). The dispenser is installed directly on the tank (standard version) or remotely from it. The distance for the remote dispenser location should not exceed 10 metres.

VERTICAL BLADDER TANK FT-V, TM DINARM

HORIZONTAL BLADDER TANK FT-H, TM DINARM

Tank with two dispensers

The vertical/horizontal tank with two dispensers is designed for projects where multiple foam agent supply lines are provided. Multiple dispensers can operate simultaneously or sequentially with the tank, depending on the project requirements. In projects featuring a ring section of pipeline with two inlets, the dispenser shall be installed in each inlet or directly in the ring. It is possible to use one tank with two dispensers, as the main and reserve volumes of the foaming agent are allowed to be stored in one container.

VERTICAL BLADDER TANK FT-V, TM DINARM, WITH TWO DISPENSERS

HORIZONTAL BLADDER TANK FT-H, TM DINARM, WITH TWO DISPENSERS

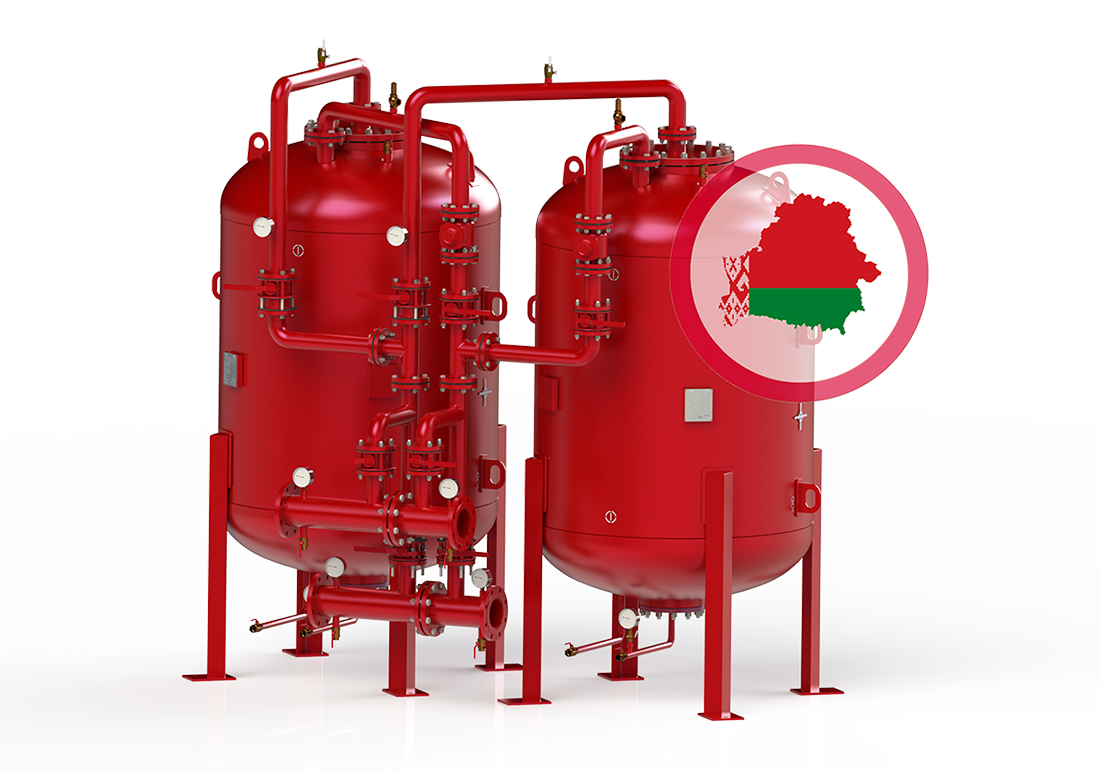

Dual bladder tanks

Dual vertical/horizontal bladder tanks are used in projects involving automatic fire suppression systems where the dimensions of the premises do not allow for the use of a single large-capacity tank.

Depending on the overall dimensions of the premises, two tanks are used, operating with one or more dispensers. When dual tanks are operated, dispensers can operate either sequentially or simultaneously, depending on the project requirements.

Depending on the overall dimensions of the premises, two tanks are used, operating with one or more dispensers. When dual tanks are operated, dispensers can operate either sequentially or simultaneously, depending on the project requirements.

DUAL VERTICAL BLADDER TANKS FT-V, TM DINARM

DUAL HORIZONTAL BLADDER TANK FT-H, TM DINARM

TEHHIM MANUFAKTURA, LLC

Tank dispensers

The tanks are fitted with a dispenser, a device responsible for mixing foaming agent displaced from the tank with a water flow in the required proportion. Three types of dispensers are used with the tanks. The dispensers are selected based on the project requirements for foam agent solution consumption:

EACH DISPENSER IS CALIBRATED AND TESTED UNDER PROJECT-SPECIFIC CONDITIONS.

Velga-AVM

diaphragm type

Velga-MK W

wide-range type

Velga-MK

high-capacity type

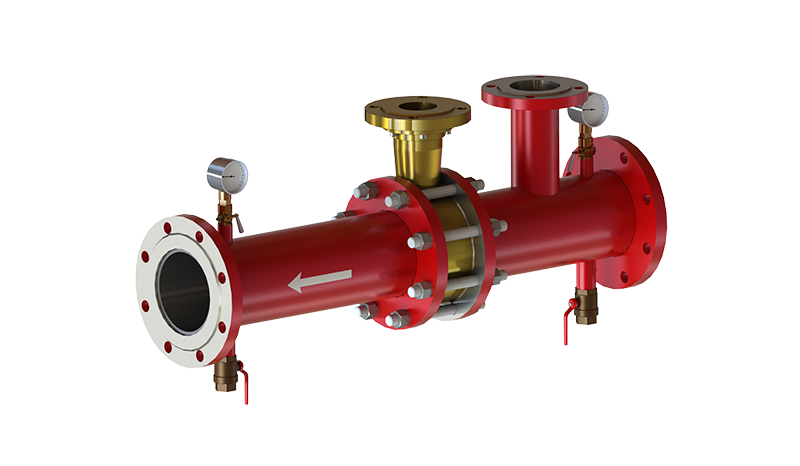

WIDE-RANGE DISPENSER (VELGA-MK W)

Wide-range dispensers are used in projects with foam agent solution flow rates within a specific range (sprinkler fire suppression systems, deluge fire suppression systems with multiple activation scenarios, facilities with multiple fire suppression directions). Due to the dispenser design, the percentage of foaming agent dispensed remains unchanged when the flow rate in the system changes.

Wide-range dispensers are manufactured in the following sizes:

- DN100; - DN150; - DN200; - DN250.

Operating principle: When water enters the dispenser, it is divided into two flows: most of the water enters the dispenser, while the rest is directed into the tank, creating pressure on the surface of the internal flexible container and forcing the foaming agent out of it into the dispenser. After passing through the opening which determines its concentration, the foaming agent enters the main water flow. Water and foaming agent are mixed producing a water-foam solution with a stable concentration.

Wide-range dispensers are manufactured in the following sizes:

- DN100; - DN150; - DN200; - DN250.

Operating principle: When water enters the dispenser, it is divided into two flows: most of the water enters the dispenser, while the rest is directed into the tank, creating pressure on the surface of the internal flexible container and forcing the foaming agent out of it into the dispenser. After passing through the opening which determines its concentration, the foaming agent enters the main water flow. Water and foaming agent are mixed producing a water-foam solution with a stable concentration.

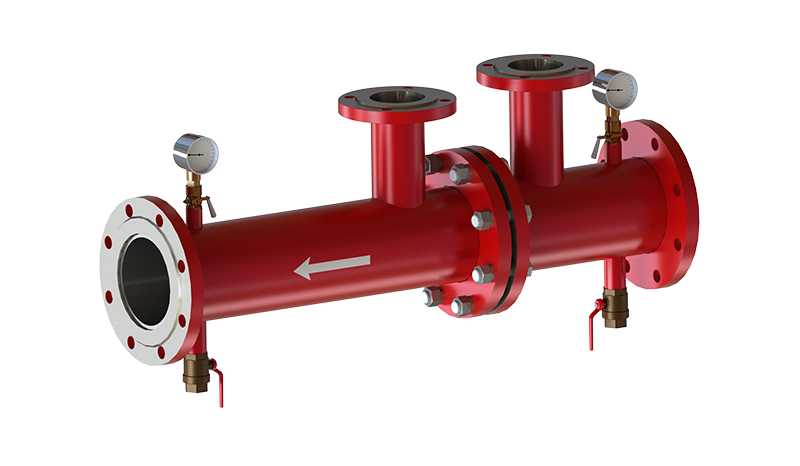

DIAPHRAGM DISPENSER (VELGA-AVM)

Diaphragm dispensers are used in projects with a constant (stable) flow rate.

Diaphragm dispensers are manufactured in the following sizes:

- DN65; - DN80; - DN100; - DN150; - DN200; - DN250.

Operating principle: Diaphragm dispensers are provided with an opening calibrated according to the required solution concentration. Once the system is activated, the flexible container inside the tank, which separates the water and the foaming agent, transfers the pressure of the water entering the tank to the foaming agent, forcing it into the dispenser, where a pressure difference is created between the dispenser inlet and the tank, depending on the water flow through the dispenser.

Upon passing through the opening which determines its concentration, the foaming agent enters the main water flow. As a result, a water-foam solution with a stable concentration is produced in the dispenser.

Diaphragm dispensers are manufactured in the following sizes:

- DN65; - DN80; - DN100; - DN150; - DN200; - DN250.

Operating principle: Diaphragm dispensers are provided with an opening calibrated according to the required solution concentration. Once the system is activated, the flexible container inside the tank, which separates the water and the foaming agent, transfers the pressure of the water entering the tank to the foaming agent, forcing it into the dispenser, where a pressure difference is created between the dispenser inlet and the tank, depending on the water flow through the dispenser.

Upon passing through the opening which determines its concentration, the foaming agent enters the main water flow. As a result, a water-foam solution with a stable concentration is produced in the dispenser.

HIGH-CAPACITY DISPENSER (VELGA-MK W)

The high-capacity dispenser is used in water and foam fire suppression systems to obtain an aqueous solution of foam agent with a specified concentration. High-capacity dispensers are variable dosing dispensers with a predetermined dosing percentage range, in which the proportioning device is performed as an element with a constant cross-section, a constant water flow passage and a variable cross-section of the adjustable foam agent flow.

The high-capacity dispenser ensures precise mixing of a foaming agent in the specified proportion.

High-capacity dispensers are manufactured in the following sizes:

- DN100; - DN150; - DN200; - DN250.

The feature of a high-capacity dispenser is its ability to operate at high flow rates, unlike a diaphragm dispenser.

The high-capacity dispenser ensures precise mixing of a foaming agent in the specified proportion.

High-capacity dispensers are manufactured in the following sizes:

- DN100; - DN150; - DN200; - DN250.

The feature of a high-capacity dispenser is its ability to operate at high flow rates, unlike a diaphragm dispenser.

TEHHIM MANUFAKTURA, LLC

ADDITIONAL EQUIPMENT

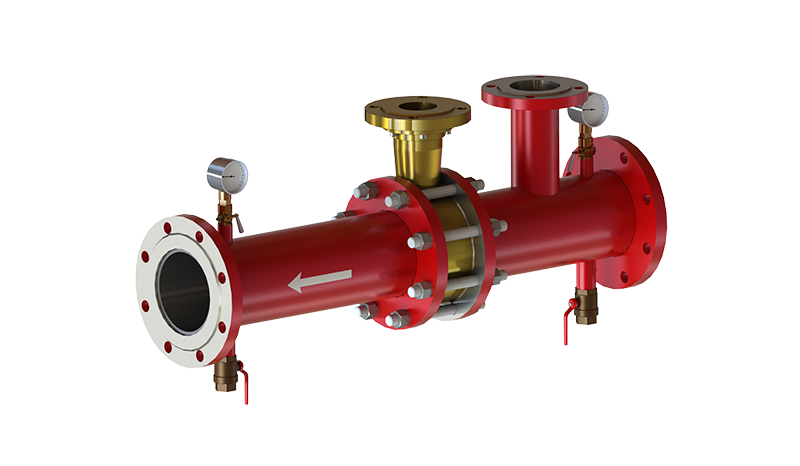

FOAM AGENT SUPPLY CONTROL VALVE (VELGA-KKP)

The foam agent supply control valve is installed in the bladder tank piping on the foam agent supply line from the tank to the dispenser. It is used in projects where the system is under filling. It is a shut-off device preventing false triggering of the tank. It opens automatically upon a signal, simultaneously with the control units of the fire suppression system.

The special "UniEpox PRO M" coating of the control valve allows its use in aggressive environments similar to those found on offshore platforms and in many industrial chemical facilities.

Foam agent supply control valve (certified according to TR EAEU 043/2017)

The foam agent supply control valve is operated automatically and/or manually.

Activation: the following devices are installed as a trigger on the foam agent supply control valve:

The special "UniEpox PRO M" coating of the control valve allows its use in aggressive environments similar to those found on offshore platforms and in many industrial chemical facilities.

Foam agent supply control valve (certified according to TR EAEU 043/2017)

DESIGN AND OPERATING PRINCIPLE

The foam agent supply control valve offers a simple and reliable design with three main components: the body, the cover, and the diaphragm. The springless diaphragm mechanism ensures uniform pressure distribution on the sealing area, prevents diaphragm deformation, and provides a longer service life.The foam agent supply control valve is operated automatically and/or manually.

Activation: the following devices are installed as a trigger on the foam agent supply control valve:

- electromagnetic (solenoid) valve (normally closed) — electric start;

- manual drain valve — manual start.

FILLING KIT FOR THE BLADDER TANK

It is intended for filling the bladder tank with a foaming agent.

Scope of supply:

Operating principle of the filling kit:

Scope of supply:

- electric pump for filling the bladder tank with foam agent;

- two 2.5-metre hoses with units for connection;

- compressor for the bladder expanding inside the tank;

- pressure gauge for monitoring pressure during bladder expanding.

Operating principle of the filling kit:

- The compressor is used to expand the flexible bladder inside the bladder tank.

- The pressure gauge is used to monitor the pressure when expanding the bladder.

- The hoses are connected. The first one is connected to the tank and pump, the second one to the pump and the foam agent container.

- With the pump, the foaming agent is pumped into the bladder tank.

The electric pump is intended for pumping foam concentrate and products similar to it in viscosity and chemical activity with a temperature not exceeding 90°C

Compressor for the bladder expanding: With this compressor, the flexible bladder in the bladder tank expands during the procedure of filling the tank with foam agent

Hoses, 2 x 2.5 metres. Necessary for connecting the pump to the bladder tank and to the foam agent container

TEHHIM MANUFAKTURA, LLC

About Us

Tekhkhim Manufaktura is a reliable partner and supplier in the fire safety industry.

We supply components for automatic fire extinguishing systems and offer our own fire protection equipment for purchase. Our products include DINARM tanks with internal flexible containers (type bladder tanks), complete with wide-range, high-capacity, or diaphragm-type dosing devices.

We supply components for automatic fire extinguishing systems and offer our own fire protection equipment for purchase. Our products include DINARM tanks with internal flexible containers (type bladder tanks), complete with wide-range, high-capacity, or diaphragm-type dosing devices.

Working Hours

Mon. - Fri. : 09.00 -17.00

© 2025 All rights reserved.